This crazy sculpture is made by an MIT-engineered machine that 3D prints biopolymers to replace plastic

"The notion of 'end of life' doesn't exist in Material Ecology, since the assumption is that every product we use, every building we inhabit, can degrade by design to fuel new growth," designer and MIT Media Lab professor Neri Oxman, who coined the term "material ecology" and led the project, says in an email. "What if we could substitute 'end of life' with 'physical incarnation'?"

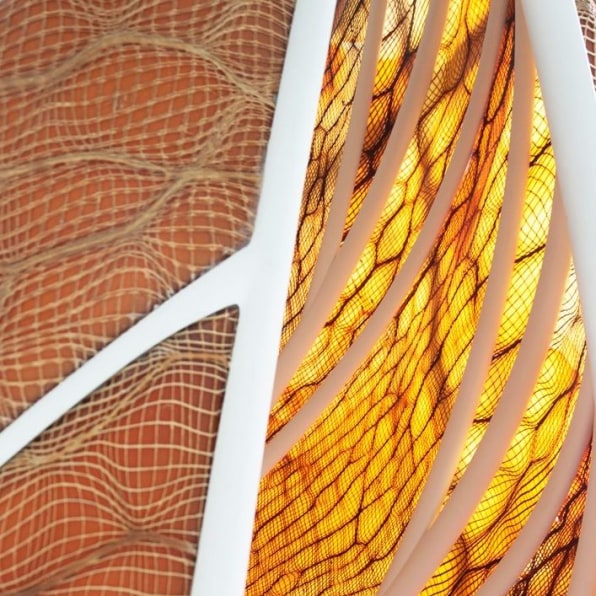

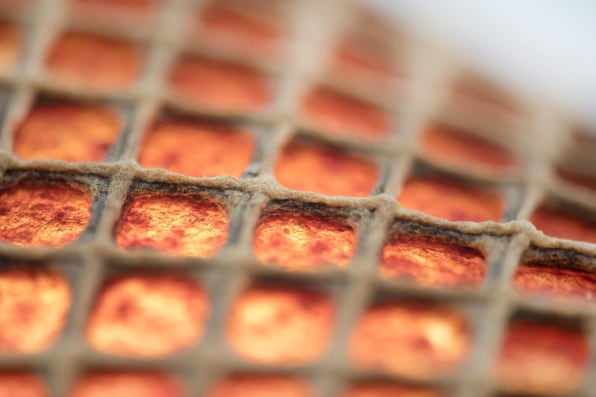

Aguahoja, the winner of the in the art and design category in Fast Company's 2020 World Changing Ideas Awards, uses a robotic platform to 3D print a plastic alternative using organic compounds from waste suspended in water. In one iteration, an architectural pavilion called Aguahoja I, 16-foot tall panels were made from a combination of chitosan (a component of shrimp shells), cellulose from plants, and pectin from apples, 3D printed in different combinations to affect the color, strength, transparency, and other attributes of the final product, including how it reacts to the outside environment.

"Each structure in the collection contains a unique combination of organic materials whose allocation, texture, and distribution within the final object are computationally driven and additively manufactured in high spatial resolution," Oxman says. "This enables control over specific physical properties and environmental adaptation to changing weather conditions. In contrast to most synthetic materials, structures included in this collection will react to their environment over their lifespan, adapting their geometry, mechanical behavior, and color in response to fluctuations in heat, humidity, and sunlight."

The final polymers "can be materially 'programmed' to decay prior to their return to the earth, for purposes of fueling new growth," she says. In the case of Aguahoja I, the structure is designed to withstand changing conditions of heat and humidity, but is programmed to degrade when it's exposed to rainwater.

While the materials avoid the problems of plastic—both in sourcing from fossil fuels and pollution problems when plastic is thrown away—they also have advantages in terms of performance, Oxman says. "Organic structures embody superior material properties compared with manmade ones. From a limited palette of molecular components, including cellulose, chitosan and pectin―the very same materials found in trees, crustaceans, and apple skins―natural systems construct an extensive array of functional materials with no synthetic parallels. . . . These materials, and the living systems they grow in, outperform human engineering not only in their diversity of functions but also in their resilience, sustainability, and adaptability."

Some biopolymers, designed for use in temporary products like packaging, could be designed to quickly degrade, while others could be designed to last. The team plans to scale up the technology so it can eventually move to mass production aand begin replacing traditional systems reliant on fossil fuels and landfills. "Aguahoja points toward a future where we subvert the industrial cycle of overproduction and obsolescence through the use of abundant natural materials," Oxman says. "With Aguahoja, we envision the ability to temporarily divert materials from healthy ecosystems, integrating them in human designs, including designing their decomposition for fueling new growth."

Komentar

Posting Komentar